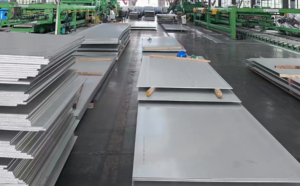

Nerūsējošā tērauda, with its exceptional corrosion resistance and durability, has become a staple in the sheet metal industry. However, with various grades and types available, choosing the best stainless steel for sheet metal applications can be a daunting task. This article aims to provide a comprehensive and authoritative overview of the various nerūsējošā tērauda markas suitable for sheet metal, considering factors such as corrosion resistance, mechanical properties, and cost-effectiveness.

Kāds ir labākais nerūsējošais tērauds lokšņu metālam?

At the forefront of stainless steel sheet metal options, we have the 300 series, which includes grades like 304 un 316. These austenitic stainless steels are non-magnetic and offer excellent corrosion resistance, making them suitable for a wide range of applications.

304 stainless steel, also known as 18/8 stainless steel due to its composition of 18% chromium and 8% nickel, is one of the most commonly used grades for sheet metal. It offers good corrosion resistance in most environments, including mildly corrosive atmospheres and freshwater. Its mechanical properties, including ductility and weldability, make it easy to fabricate into various shapes and sizes. Additionally, 304 stainless steel is relatively cost-effective, further adding to its popularity.

However, for applications that require even higher corrosion resistance, especially in marine or chloride-rich environments, 316 stainless steel is a better choice. 316 stainless steel contains molybdenum, which significantly enhances its resistance to corrosion by chloride ions. This grade is often used in coastal areas, chemical processing plants, and other high-corrosion environments. While 316 stainless steel is more expensive than 304, its superior corrosion resistance often justifies the higher cost.

Another notable stainless steel grade for sheet metal is 430. This ferritic stainless steel contains a higher chromium content than the 300 series, providing good corrosion resistance, but it is less ductile and more prone to rusting in certain environments. Its magnetic properties and lower cost make it suitable for applications where aesthetics and corrosion resistance are less critical.

For applications that require high strength and wear resistance, martensitic stainless steels like 410 and 440C may be considered. These grades offer excellent mechanical properties but are less corrosion-resistant than the austenitic and ferritic grades. They are often used in tools, knives, and other applications where hardness and wear resistance are paramount.

Dual-phase stainless steels, such as 2205, offer a unique combination of corrosion resistance and mechanical properties. These alloys contain both austenite and ferrite phases, resulting in improved strength and toughness compared to single-phase stainless steels. They are often used in demanding applications that require both corrosion resistance and high mechanical performance.

When selecting the best stainless steel for sheet metal, it is essential to consider the specific requirements of the application. Corrosion resistance, mechanical properties, cost, and fabrication ease are all critical factors that need to be balanced. For example, if the sheet metal will be exposed to harsh chemicals or seawater, corrosion resistance should be the primary concern, favoring grades like 316 or dual-phase stainless steels. On the other hand, if cost is a limiting factor, and corrosion resistance requirements are less severe, 430 or even lower-grade stainless steels may be suitable.

Fabrication considerations are also crucial. Austenīta nerūsējošie tēraudi like 304 and 316 are generally easier to weld and form than ferritic or martensitic grades. This makes them more suitable for complex shapes and intricate designs. However, martensitic stainless steels may be preferred for applications that require high hardness and wear resistance.

Secinājumi

In conclusion, the best stainless steel for sheet metal depends on the specific requirements of the application. It is crucial to carefully evaluate corrosion resistance, mechanical properties, cost, and fabrication ease to make an informed decision. With the wide range of stainless steel grades available, there is sure to be an option that meets the needs of any sheet metal application.

Thank you for reading our article and we hope you’ve enjoyed it. If you are looking for stainless steel supplier and manufacturer online now, we would advise you to visit Sino Stainless Steel.

Kā vadošais nerūsējošā tērauda izstrādājumu piegādātājs no Šanhajas Ķīnas, Sino Stainless Steel piedāvā klientiem augstas kvalitātes nerūsējošā tērauda spoles, nerūsējošā tērauda dekoratīvās loksnes, nerūsējošā tērauda caurules, nerūsējošā tērauda caurules, nerūsējošā tērauda sloksnes, nerūsējošā tērauda plāksnes, un nerūsējošā tērauda stieņi par ļoti konkurētspējīgu cenu.

86 + 18621535697-XNUMX

86 + 18621535697-XNUMX  :export81@huaxia-intl.com

:export81@huaxia-intl.com